Packaging Equipment & Films wants to earn your tape business. The following offer is for a free case of 2” x 110 yd. 1.9 mil hot melt carton sealing tape. The offer is for a limited time and the list of restrictions applies.

1) One (1) case of tape per customer

2) Offer is limited to the states of Indiana and Ohio

3) Freight is the responsibility of the customer

4) Customer must supply current tape in use, annual volume, ship to address

5) Actual product supplied is at the discretion of PEF

6) Offer has no cash value

7) Offer valid while supplies last

8) Offer applies to new tape customers of PEF

Please call Harold at 317-773-8397 to place your order

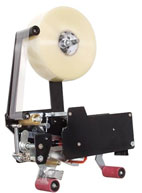

Last month a customer/supplier of printed digital labels contacted us for assistance on an application to apply labels to whiskey and vodka bottles for a start-up micro distillery. Hand applying labels to the front and back of the bottle was a tedious and inconsistent process that was adding a significant amount of laber cost to their process. The volume was not enough to warrant an inline high speed application, due the batch size of each distilled spirit; also the bottle was taper styled glass container.

Last month a customer/supplier of printed digital labels contacted us for assistance on an application to apply labels to whiskey and vodka bottles for a start-up micro distillery. Hand applying labels to the front and back of the bottle was a tedious and inconsistent process that was adding a significant amount of laber cost to their process. The volume was not enough to warrant an inline high speed application, due the batch size of each distilled spirit; also the bottle was taper styled glass container.